Professional Engineering Design

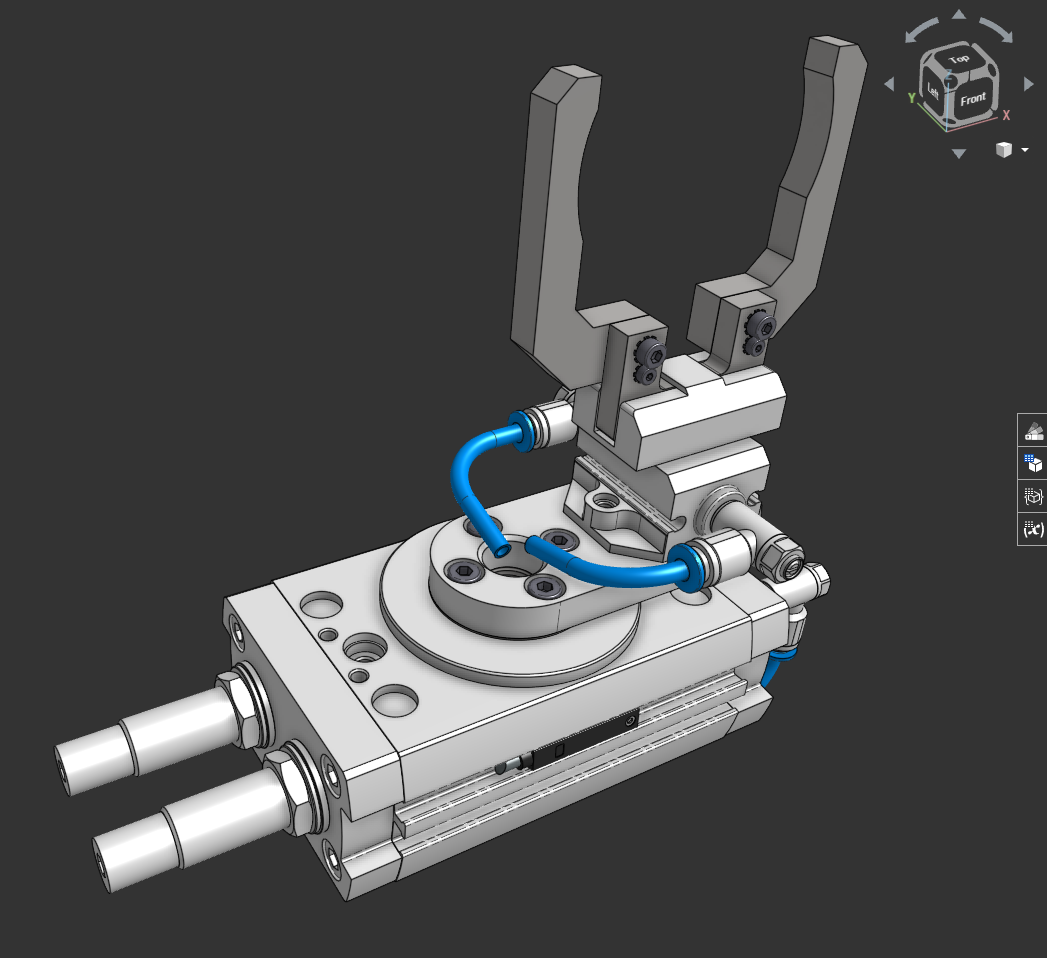

Chartered mechanical engineer with 15+ years of experience in technical product development. Specialising in efficient, agile prototype development under tight timelines & budgets.

I'm James, an independent Chartered Mechanical Engineer. I help founders, start-ups, and scientists turn ideas into working products fast, from first prototypes to production-ready designs.

My approach is experimental and fast-moving. We can build early, test often and refine quickly. Each iteration de-risks the design, surfaces the real engineering challenges and brings you closer to a product that works in practice, not just on paper.

You will gain access to my trusted network of technical, design and manufacturing experts. Together we move quickly, keep spending tight and give your ideas the best chance of success.

| First prototypes to production-ready designs |

| Research tools and test equipment |

| Investor-demo hardware |

| Tight budgets and timelines |

| Short, iterative build–test loops |

| Slot-in support for larger teams |

Flexibility

Every project follows its own unique path. Instead of a rigid, one-size-fits-all process, I use a flexible framework of stages that can be added, removed or re-ordered to fit the job.

Modern Tools

You get in-browser reviews, controlled revisions, a single shared space for files and comments, enterprise grade security and resilient continuous backups.

| Faster Feedback: Open the live model in the browser and comment directly. |

| Version Control: All changes are version controlled, so we can revert at any time. |

| Shared Space: All project data lives in a secure, shared space. |

| Explore Freely: Branching and merging allows exploration of multiple design ideas, simultaneously. |

| Secure & Resilient: Enterprise-grade security and continuous backups. |

Onshape is my preferred software for creating 3D models. I'm also experienced with SolidWorks, Creo, and Inventor, and can usually work in whichever CAD tool your project needs.

Previous Career Snapshots

TTP Electro-mechanical systems for life science

Mechanical engineering consultant delivering electromechanical solutions for life-science instruments. I worked hands-on across optics, thermal control, pneumatics, and microfluidics, from CAD and analysis to prototype build and test. Tools included Onshape, Creo, SolidWorks, and Python for modelling and control.

Blacktrace Scientific and laboratory equipment

Mechanical design engineer turning biotech and flow-chemistry concepts into production hardware. Full product development lifecycle: concept to CAD in PTC Creo with Windchill, electronics integration, and test builds. Wrote C# and Python tools, ran DFMEAs, and built jigs to speed production and improve quality.

AXISCADES CAE/FEA

UK CAE project manager delivering FEA and analytical models for design validation and specification. I produced technical reports, advised clients, and led remote teams in India to deliver safety-critical mechanical analyses. Tools: PTC Creo/Simulate, Inventor, MATLAB, Altair HyperWorks.

Intelligent Energy Fuel-cell modules

Mechanical design engineer on evaporatively cooled hydrogen fuel-cell systems. Designed low-voltage modules and cell stacks, ran FEA, and took concepts to lab rigs and prototype tests. SolidWorks with PDM; statistical analysis to drive design decisions.

Terex Quarry equipment

Design engineer on the Terex jaw-crusher team in Coalville. Built heavy machinery in Creo and Simulate with Pulse PDM, designing for machining, casting, and fabrication, and running quarry trials. Progressed into crushing-chamber FEA, fatigue assessment, and a Python wear model; designed and validated lifting accessories to BS EN 13001; represented Terex in the National Engineering Education Scheme.

Approach

- Do less, do it better.

- Keep it simple.

- Prototype early, fail fast, learn quickly.

Qualifications and Training

- 15+ Years in Technical Product Development and Consulting

- Chartered Mechanical Engineer (CEng, MIMechE)

- MEng, Mechanical Engineering (1st)

- MSc, Intelligent Systems & Robotics (1st)

- PhD, Computer Science (in progress)

- GD&T Training

- Onshape, Solidworks and Creo Training

- Medical diagnostic equipment

- Carbon capture systems

- Packaging machines

- Industrial freezer systems

- Rock crushing equipment

- Laboratory automation equipment

- Cell therapy systems

- Fuel storage tanks

- PCR Machines

- Printers

- Dakar race vehicles

- Microscopes

- Cell sorting machines

- Telehandlers

- Hydrogen fuel cell systems

- Medical consumables

Let's connect

Whether you want to explore ideas, discuss a project or just chat through possibilities, I'm always open to a conversation.